SINTERING PLANTS

SINTERING PLANTS

In the heart of blast furnace

The sintering plant

supplies the agglomerated blast furnace,

a mixture of minerals, fluxes and cok

partially "cooked" or sintered.

This mixture, properly weighed and dosed,

passes on a conveyor belt

until reaching the mixing drum,

where, once the water is added,

it is then burned in the ignition hood.

SINTERING PLANTS

STEEL INDUSTRY SPECIAL SECTIONS

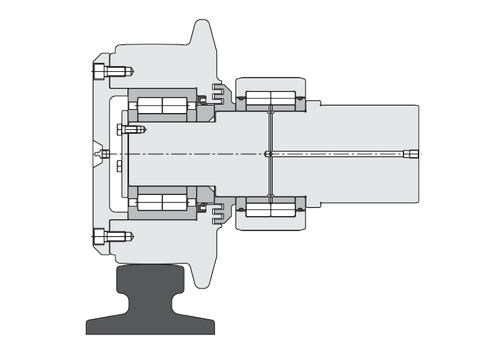

PRESSURE ROLLS

C.R. has developed a series of bearings suitable to work under extremely heavy and difficult conditions.

The sintering line is one of the main strategic issues in the steel plants, as the line that carries the ferrous material never stops.

The load applied is very high, dust and high temperature contribute to determine the worst possible working condition.

WHEELS

Both the outer ring and the inner ring of the bearings are made in 100CrMo7 core hardened steel. FKM (Viton) seals are inserted in the sides, in order to prevent dust to enter the roller and this increases the lifetime of the bearings.

The rings undergo bainitic tempering treatment. The choice of the lubricant and its quantity are very important.

This is the reason why C.R. uses special lithium soap greases, specifically used in cases of very high pressure.