Single cylindrical back-up rollers (execution in inches)

Steel Industry - Single cylindrical back-up rollers (execution in inches)

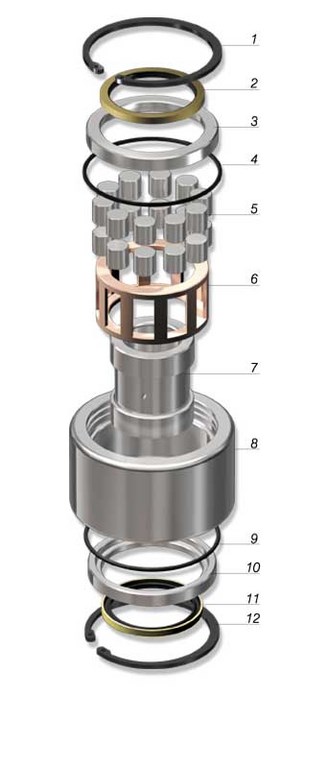

Technical Drawing and Exploded View - Single cylindrical back-up rollers (execution in inches)

Technical Data - Single cylindrical back-up rollers (execution in inches)

| C.R. rif / ref | A (mm/in) | B (mm/in) | C (mm/in) | D (mm/in) | Cw (Radial N / Lbf) |

|---|---|---|---|---|---|

| 100-0001 | 7.938 | 28.575 | 22.225 | 21.463 | 8970 |

| 100-0001 | 0.3125 | 11.250 | 0.8750 | 0.8450 | 2016 |

| 100-0002 | 11.113 | 38.100 | 28.578 | 26.988 | 14340 |

| 100-0002 | 0.4375 | 15.000 | 11.251 | 10.625 | 3240 |

| 100-0003 | 12.700 | 41.275 | 28.578 | 26.988 | 16500 |

| 100-0003 | 0.500 | 16.250 | 11.251 | 10.625 | 3720 |

| 100-0004 | 12.700 | 44.450 | 28.578 | 26.988 | 16500 |

| 100-0004 | 0.500 | 17.500 | 11.251 | 10.625 | 3720 |

| 100-0005 | 15.875 | 50.800 | 36.515 | 34.925 | 30000 |

| 100-0005 | 0.6250 | 20.000 | 14.376 | 13.750 | 6780 |

| 100-0006 | 15.875 | 52.388 | 36.515 | 34.925 | 30000 |

| 100-0006 | 0.6250 | 20.625 | 14.376 | 13.750 | 6780 |

| 100-0007 | 15.875 | 53.975 | 36.515 | 34.925 | 30000 |

| 100-0007 | 0.6250 | 21.250 | 14.376 | 13.750 | 6780 |

| 100-0008 | 19.050 | 57.150 | 34.928 | 33.338 | 33600 |

| 100-0008 | 0.7500 | 22.500 | 13.751 | 13.125 | 7530 |

| 100-0009 | 19.050 | 63.500 | 34.928 | 33.338 | 33600 |

| 100-0009 | 0.7500 | 25.000 | 13.751 | 13.125 | 7530 |

| 100-0010 | 20.638 | 76.200 | 48.423 | 46.883 | 54600 |

| 100-0010 | 0.8125 | 30.000 | 19.064 | 18.438 | 12300 |

| 100-0011 | 30.005 | 85.725 | 50.800 | 49.213 | 63300 |

| 100-0011 | 11.813 | 33.750 | 20.000 | 19.375 | 14250 |

| 100-0012 | 30.005 | 88.900 | 50.800 | 49.213 | 63300 |

| 100-0012 | 11.813 | 35.000 | 20.000 | 19.375 | 14250 |

| 100-0013 | 38.100 | 101.600 | 58.735 | 57.150 | 94800 |

| 100-0013 | 15.000 | 40.000 | 23.124 | 22.500 | 21300 |

| 100-0014 | 38.100 | 107.950 | 58.735 | 57.150 | 94800 |

| 100-0014 | 15.000 | 42.500 | 23.124 | 22.500 | 21300 |

| 100-0015 | 44.450 | 127.000 | 66.673 | 65.088 | 159000 |

| 100-0015 | 17.500 | 50.000 | 26.249 | 25.625 | 35700 |

| 100-0016 | 44.450 | 127.000 | 71.438 | 65.088 | 159000 |

| 100-0016 | 17.500 | 50.000 | 28.125 | 25.625 | 35700 |

| 100-0017 | 50.800 | 120.650 | 69.850 | 68.265 | 162600 |

| 100-0017 | 20.000 | 47.500 | 27.500 | 26.876 | 36600 |

| 100-0018 | 50.800 | 127.000 | 69.850 | 68.265 | 162600 |

| 100-0018 | 20.000 | 50.000 | 27.500 | 26.876 | 36600 |

| 100-0019 | 53.975 | 120.650 | 69.850 | 68.265 | 162600 |

| 100-0019 | 21.250 | 47.500 | 27.500 | 26.876 | 36600 |

| 100-0020 | 53.975 | 127.000 | 69.850 | 69.850 | 162600 |

| 100-0020 | 21.250 | 50.000 | 27.500 | 27.500 | 36600 |

| 100-0021 | 53.975 | 152.400 | 69.850 | 69.850 | 162600 |

| 100-0021 | 21.250 | 60.000 | 27.500 | 27.500 | 36600 |

| 100-0022 | 60.000 | 142.875 | 65.090 | 65.090 | 179700 |

| 100-0022 | 23.622 | 56.250 | 25.626 | 25.626 | 40500 |

| 100-0023 | 60.000 | 149.225 | 65.090 | 65.090 | 179700 |

| 100-0023 | 23.622 | 58.750 | 25.626 | 25.626 | 40500 |

| 100-0024 | 69.850 | 177.800 | 69.850 | 69.850 | 179700 |

| 100-0024 | 27.500 | 70.000 | 27.500 | 27.500 | 40500 |

| 100-0025 | 70.000 | 149.225 | 74.615 | 74.615 | 179700 |

| 100-0025 | 27.559 | 58.750 | 29.376 | 29.376 | 40500 |

| 100-0026 | 70.000 | 158.750 | 74.615 | 74.615 | 179700 |

| 100-0026 | 27.559 | 62.500 | 29.376 | 29.376 | 40500 |

| 100-0027 | 70.000 | 159.974 | 74.615 | 74.615 | 179700 |

| 100-0027 | 27.559 | 62.982 | 29.376 | 29.376 | 40500 |

| 100-0028 | 70.000 | 177.800 | 74.615 | 74.615 | 179700 |

| 100-0028 | 27.559 | 70.000 | 29.376 | 29.376 | 40500 |

| 100-0029 | 70.000 | 199.974 | 74.615 | 74.615 | 179700 |

| 100-0029 | 27.559 | 78.730 | 29.376 | 29.376 | 40500 |

| 100-0030 | 70.000 | 203.200 | 74.615 | 74.615 | 179700 |

| 100-0030 | 27.559 | 80.000 | 29.376 | 29.376 | 40500 |

| 100-0031 | 70.000 | 228.600 | 74.615 | 74.615 | 179700 |

| 100-0031 | 27.559 | 90.000 | 29.376 | 29.376 | 40500 |

| 100-0032 | 71.438 | 177.800 | 98.422 | 98.422 | 339000 |

| 100-0032 | 28.125 | 70.000 | 28.749 | 28.749 | 75900 |

| 100-0033 | 85.725 | 158.750 | 73.025 | 73.025 | 193800 |

| 100-0033 | 33.750 | 62.500 | 28.750 | 28.750 | 43500 |

| 100-0034 | 85.725 | 203.200 | 73.025 | 73.025 | 193800 |

| 100-0034 | 33.750 | 80.000 | 28.750 | 28.750 | 43500 |

| 100-0035 | 88.900 | 206.375 | 104.775 | 104.775 | 411000 |

| 100-0035 | 35.000 | 81.250 | 41.250 | 41.250 | 92100 |

| 100-0036 | 88.900 | 249.974 | 92.075 | 92.075 | 270900 |

| 100-0036 | 35.000 | 98.415 | 36.250 | 36.250 | 60900 |

| 100-0037 | 88.900 | 250.825 | 92.075 | 92.075 | 270900 |

| 100-0037 | 35.000 | 98.750 | 36.250 | 36.250 | 60900 |

| 100-0038 | 101.600 | 260.350 | 136.525 | 136.525 | 669000 |

| 100-0038 | 40.000 | 102.500 | 53.750 | 53.750 | 150300 |

Cw: Static load

Technical Characteristics - Single cylindrical back-up rollers (execution in inches)

The single cylindrical back-up roller executed in inches is manufactured as alternative to the same series with tapered rollers.

The bearing is extremely tough and massive; it is made of one outer ring – which makes a unique body, once linked to the lateral thrust rings – and of an inner ring with entire borders, from which the rolling raceway comes out.

The bearing is extremely tough and massive; it is made of one outer ring – which makes a unique body, once linked to the lateral thrust rings – and of an inner ring with entire borders, from which the rolling raceway comes out.

This series can be manufactured with cages or with full-complement of cylindrical rollers.

- This back up roller is particularly suitable to work with high radial loads; thanks to its toughness, it maintains all its primary technical characteristics for a long flattening lifetime.

- The entire borders made from the inner ring allow to bear the axial thrusts.

- The single back-up roller with cylindrical rollers (execution in inches) has the following characteristics:

- The outer ring and the inner ring are manufactured in case hardened UNI 100Cr6/SAE 52100 steel.

- They reach hardness degree of 60+2 HRC.

- Usually, the cages are made in bronze; in some cases, when the dimensions are small, the cage can be manufactured in press-forged sheet.

- The sealing system is highly efficient, because it prevents outer agents (dust, mill scale and humidity) to enter the back-up roller; at the same time it prevents the leakage of grease. Grease lubrication is made through a groove on the inner ring.

- Precision class P0. It can be manufactured with precision class P5, on request.

- On request, they can be manufactured in stainless steel.