PWKR cam follower

Track rollers - PWKR cam follower

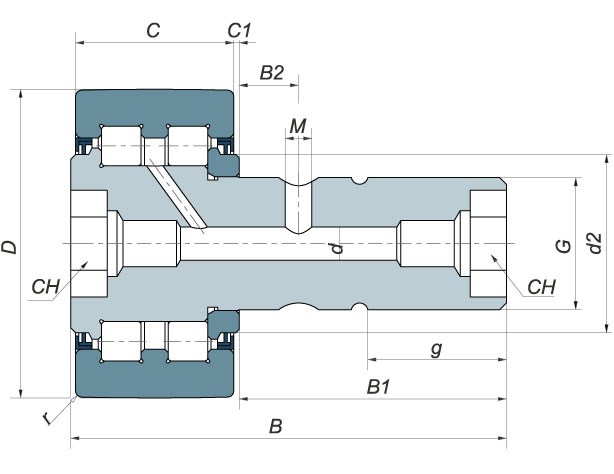

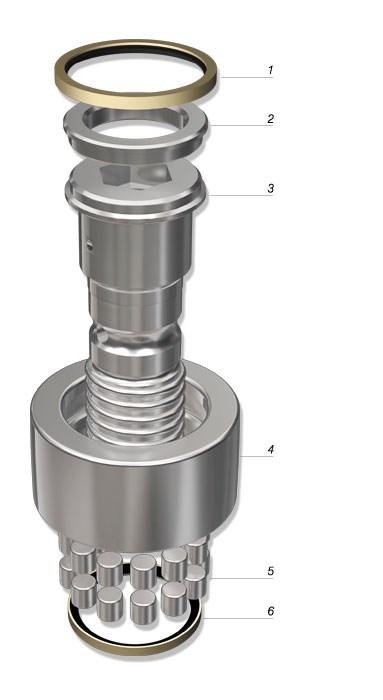

Technical Drawing and Exploded View - PWKR cam follower

2. Support thrust ring

3. Pivot

4. Outer ring

5. Cylindrical rollers

6. Zrs seal ring

Technical Data - PWKR cam follower

| CR rif/ref | D (mm) | d(h7) (mm) | c (mm) | rmin (mm) | B (mm) | B1 (mm) | B2 (mm) | G (mm) | g (mm) | M (mm) | C1 (mm) | d2 (mm) | CH (mm) | Cw (kN) | Cow (kN) | Vel Max Speed RPM min-1 | Coppia serr. Dado / Nut locking couple (Nm) Cm3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PWKR 35 2RS | 35 | 16 | 18 | 0,6 | 52 | 32,5 | 7,8 | M16x1,5 | 17 | 3 | 0,8 | 20 | 8 | 11,6 | 11,3 | 6000 | 58 |

| PWKR 40 2RS | 40 | 18 | 20 | 1 | 58 | 36,5 | 8 | M18x1,5 | 19 | 3 | 0,8 | 22 | 8 | 13,2 | 13,8 | 5000 | 87 |

| PWKR 47 2RS | 47 | 20 | 24 | 1 | 66 | 40,5 | 9 | M20x1,5 | 21 | 4 | 0,8 | 27 | 10 | 23,2 | 25,5 | 3800 | 120 |

| PWKR 52 2RS | 52 | 20 | 24 | 1 | 66 | 40,5 | 9 | M20x1,5 | 21 | 4 | 0,8 | 31 | 10 | 24,2 | 28 | 3800 | 120 |

| PWKR 62 2RS | 62 | 24 | 28 | 1 | 80 | 49,5 | 11 | M24x1,5 | 25 | 4 | 1,3 | 38 | 14 | 35 | 39,5 | 2200 | 220 |

| PWKR 72 2RS | 72 | 24 | 28 | 1,1 | 80 | 49,5 | 11 | M24x1,5 | 25 | 4 | 1,3 | 44 | 14 | 38,5 | 46,5 | 2200 | 220 |

| PWKR 80 2RS | 80 | 30 | 35 | 1,1 | 100 | 63 | 15 | M30x1,5 | 32 | 4 | 1 | 47 | 14 | 56 | 70 | 1800 | 450 |

| PWKR 90 2RS | 90 | 30 | 35 | 1,1 | 100 | 63 | 15 | M30x1,5 | 32 | 4 | 1 | 47 | 14 | 63 | 82 | 1800 | 450 |

Pressure greaser

NIP A2x7,5: PWKR 35 2RS - PWKR 40 2RS - PWKR 47 2RS - PWKR 52 2RS

NIP A3x9,5: PWKR 62 2RS - PWKR 72 2RS - PWKR 80 2RS - PWKR 90 2RS

Adaptor for central lubrication

AP8: PWKR 35 2RS - PWKR 40 2RS

AP10: PWKR 47 2RS - PWKR 52 2RS

AP14: PWKR 62 2RS - PWKR 72 2RS - PWKR 80 2RS - PWKR 90 2RS

Cw: Dynamic load - Cow: Static load

Technical Characteristics - PWKR cam follower

The main characteristic of this series of rollers is the high thickness of the outer ring, which is suitable to bear specific high pressures and the impacts that characterize the use of these bearings (ex. cam followers).

It differs from NUKR series as far as the characteristics of the seals are concerned, as they are of ZRS type (steel and rubber). Furthermore, a chamber for the lubrication grease is foreseen between the rolling raceways of the outer ring.

- Outer ring with double border of the rollers obtained entirely and accurately grinded to allow the roller to bear loads with axial components. The ring is usually cambered on the outer part, in order to improve working condition with heavy loads and to prevent the concentration of load onto side bands of the raceway. On request, C.R. can supply rollers with cylindrical outer surface.

- Pivot with threaded shank, one guide border of rollers obtained entirely and tempered rolling raceway. On the front part, a seat for hexagon wrench or for corkscrew (on request) are foreseen.

- The ZRS seals forced on the outer ring guarantee an extremely efficient protection system.

- Full complement of grinded flat head cylindrical rollers.

- Lubrication channels and holes in the pivot.

- Tolerance of execution according to normal class, possibility of special execution according to class P5 (DIN 620).