Pressure rolls

Steel Industry - Pressure rolls

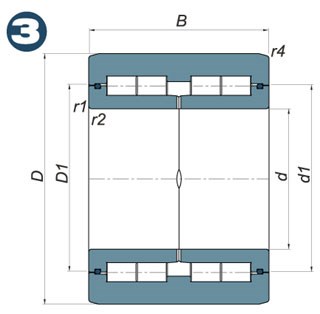

Technical Drawing and Exploded View - Pressure rolls

Technical Data - Pressure rolls

| C.R. rif / ref | d (mm) | d1 (mm) | D (mm) | D1 (mm) | B (mm) | r1,2 min. (mm) | r3,4 min. (mm) | Esec tipo / type | C (KW) | Co (KW) | Cw (KW) | Cow (KW) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 900-2340 | 93 | 126 | 170 | 127 | 95 | 2 | 10x15° | 1 TB2 | 429 | 655 | 286 | 390 |

| 900-3852 | 100 | 148 | 200 | 149 | 114 | 4 | 10X15° | 1 TB2 | 605 | 1000 | 413 | 600 |

| 900-3853 | 105 | 151 | 215 | 153 | 87 | 3 | 3 | 2 TB1 | 501 | 695 | 358 | 450 |

| 900-2339 | 110 | 157 | 210 | 158 | 110 | 2 | 10X15° | 1 TB2 | 402 | 610 | 255 | 325 |

| 900-2818 | 120 | 157 | 210 | 158 | 114 | 4 | 10X15° | 1 TB2 | 550 | 915 | 330 | 455 |

| 900-3854 | 128,665 | 160 | 210 | 162 | 114 | 4 | 10X15° | 1 TB2 | 583 | 1120 | 352 | 560 |

| 900-3855 | 140 | 178 | 250 | 180 | 110 | 3 | 11.5X17° | 1 | 825 | 1400 | 561 | 850 |

| 900-3446 | 140 | 187 | 250 | 188 | 114 | 3 | 13.5X17° | 1 | 825 | 1400 | 512 | 750 |

| 900-3856 | 140 | 187 | 280 | 188 | 114 | 3 | 13.5X15° | 1 TB1 | 913 | 1460 | 671 | 1000 |

| 900-3857 | 160 | 195 | 250 | 197 | 140 | 3 | 13.5X17° | 3 TB1 | 2120 | 4400 | 1100 | 1830 |

| 900-3858 | 160 | 231 | 320 | 233 | 120 | 4 | 13X17° | 1 | 1140 | 2040 | 737 | 1140 |

| 900-3859 | 160 | 227 | 330 | 228 | 140 | 4 | 6.5X15° | 1 | 1140 | 2040 | 825 | 1340 |

| 900-3860 | 180 | 238 | 330 | 240 | 125 | 4 | 6.5X15° | 1 | 968 | 1930 | 644 | 1100 |

Bearing:

C: Dynamic load - Co: Static load

Roller

Cw: Dynamic load - Cow: Static load

Notes:

TB1= bainitic temper of inner and outer ring

TB2= bainitic temper of outer ring

Technical Characteristics - Pressure rolls

C.R. pressure rolls are mainly used in the continuous furnaces of sintering plants. They are massive bearings ready to be fixed.

They are used with heavy loads and where the rotation reverses continuously at low speed.

The outer ring shows three entire borders, one section and one outer surface which is highly resistant to wear.

The inner ring is made of two parts, each one has an entire border expressly developed in order to bear high axial thrusts, in addition to radial loads.

Pressure rolls do not need maintenance.

C.R. pressure rolls have the following technical characteristics:

- The outer ring and the inner ring are manufactured in core-hardened UNI 100CrMo7 steel.

- This type of steel guarantees an excellent distribution of core-hardening.

- The degree of hardness is 60-2 HRC.

- In order to increase the resistance to wear – due to high load and contamination of outer agents – pressure rolls usually undergo bainitic temper treatment with the following suffixes: TB1 means bainitic temper of both rings, TB2 means bainitic temper only of the outer ring.

- Pressure rolls usually work at high temperatures, therefore they undergo stabilization treatment up to 250° C, named S2.

- The sealing system foresees the presence of Viton O-rings, which are inserted in the proper grooves on the inner ring. The seals allow the bearing to be disassembled, they prevent the entrance of contaminating agents and in the meantime, the leakage of lubricant.