Back-up rollers with pivot for metal flattening machines

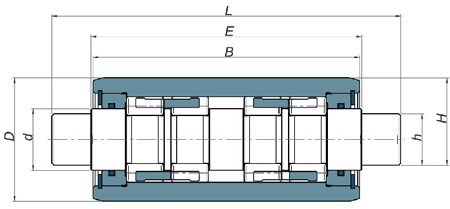

Technical Drawing and Exploded View - Back-up rollers with pivot for metal flattening machines

1. Seeger locking ring

2. Fey seal ring

3. Support thrust ring

4. O-ring seal

5. Outer ring

6. O-ring seal

7. Support thrust ring

8. Fey seal ring

9. Seeger locking ring

10. O-ring seal

11. Cylindrical rollers

12. Cage

13. Support little thrust ring

14. Seeger seal ring

15. Pivot

16. Seeger seal ring

17. Support little thrust ring

18. Cage

19. Cylindrical rollers

Technical Data - Back-up rollers with pivot for metal flattening machines

| C.R. rif / ref | Ø est. (mm) | Sigla | D (mm) | d (mm) | L (mm) | B (mm) | E (mm) | h (mm) | Tenute / Seal PDA | File rulli / Rollers Rows | Gabbie / cages | Cw (KW) | Cow (KW) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300-0003 | 47 | CRAT 47X20X155 | 47 | 20 | 155 | 125 | 126 | - | - | 4 | • | 57,2 | 65,9 |

| 300-0004 | 47 | CRAT 47X22X145 | 47 | 22 | 145 | 115 | - | 21 | - | 2 | • | 46,4 | 49,2 |

| 300-0005 | 50 | CRAT 50X20X165 | 50 | 20 | 166 | 128 | 130 | - | • | 4 | • | 69,1 | 83,2 |

| 300-0006 | 52 | CRAT 52X20X55 | 52 | 20 | 55 | 24 | 27,4 | - | - | 2 | - | 33 | 43 |

| 300-0007 | 52 | CRAT 52X20X125 | 52 | 20 | 125 | 94 | 95 | - | - | 4 | • | 65,1 | 77,7 |

| 300-0008 | 55 | CRAT 55X25X159.5 | 55 | 25 | 159,5 | 125 | - | 21 | - | 4 | • | 100,4 | 131,8 |

| 300-0009 | 60 | CRAT 60X25X90 | 60 | 25 | 90 | 50 | 52 | - | • | 2 | • | 36,2 | 43 |

| 300-0010 | 60 | CRAT 60X25X160 | 60 | 25 | 160 | 130 | 132 | - | • | 2 | • | 71,3 | 84,3 |

| 300-0011 | 60 | CRAT 60X25X170 | 60 | 25 | 170 | 130 | 132 | - | • | 2 | • | 71,3 | 84,3 |

| 300-0012 | 60 | CRAT 60X30X151.25 | 60 | 30 | 151,25 | 109,25 | 111,3 | 27 | • | 2 | • | 70,2 | 82 |

| 300-0013 | 60 | CRAT 60X30X189 | 60 | 30 | 189 | 160,3 | - | 25 | - | 2 | • | 72,4 | 85,3 |

| 300-0014 | 60 | CRAT 60X30X201 | 60 | 30 | 201 | 160,3 | - | - | • | 2 | • | 72,4 | 85,3 |

| 300-0015 | 60 | CRAT 60X30X202 | 60 | 30 | 202 | 160,3 | 162 | 27 | • | 2 | • | 72,4 | 85,3 |

| 300-0016 | 65 | CRAT 65X25X198 | 65 | 25 | 198 | 156 | 168 | 21,5 | - | 4 | • | 124,2 | 170,6 |

| 300-0017 | 75 | CRAT 75X40X165 | 75 | 40 | 165 | 140 | 143 | 29,5 | - | 4 | - | 149 | 208,5 |

| 300-0018 | 76 | CRAT 76X40X165 | 76 | 40 | 165 | 140 | 143 | 30 | - | 4 | - | 152,3 | 213,8 |

| 300-0019 | 80 | CRAT 80X35X201 | 80 | 35 | 201 | 160,3 | - | - | • | 2 | • | 111,2 | 115,6 |

| 300-0020 | 80 | CRAT 80X35X210 | 80 | 35 | 210 | 170 | - | - | • | 2 | • | 111,2 | 115,6 |

| 300-0021 | 80 | CRAT 80X35X230 | 80 | 35 | 230 | 200 | - | 30,5 | - | 2 | • | 114,5 | 118,8 |

| 300-0022 | 80 | CRAT 80X35X302.5 | 80 | 35 | 302,5 | 261,8 | - | - | • | 2 | • | 111,2 | 115,6 |

| 300-0023 | 80 | CRAT 80X40X180 | 80 | 40 | 180 | 140 | 143 | - | • | 4 | • | 127,5 | 171,7 |

| 300-0024 | 80 | CRAT 80X40X210 | 80 | 40 | 210 | 150 | 156 | - | - | 4 | • | 136 | 188 |

| 300-0025 | 90 | CRAT 90X45X134.3 | 90 | 45 | 134,3 | 100 | 102 | - | • | 2 | - | 139,3 | 167,4 |

| 300-0026 | 90 | CRAT 90X45X140 | 90 | 45 | 140 | 100 | 102 | - | • | 2 | - | 157,7 | 195,5 |

| 300-0027 | 95 | CRAT 95X45X288 | 95 | 45 | 288 | 236 | 240 | - | • | 2 | • | 173,9 | 229 |

| 300-0028 | 95 | CRAT 95X45X362 | 95 | 45 | 362 | 310 | 314 | - | • | 2 | • | 179,3 | 238,7 |

| 300-0029 | 100 | CRAT 100X45X245 | 100 | 45 | 245 | 200 | 201,4 | - | • | 2 | • | 175 | 231,1 |

| 300-0030 | 100 | CRAT 100X45X246 | 100 | 45 | 246 | 200 | 201,4 | - | • | 2 | • | 175 | 231,1 |

| 300-0031 | 100 | CRAT 100X45X246 | 100 | 45 | 246 | 200 | 201,4 | - | • | 4 | • | 280,8 | 415,8 |

| 300-0032 | 134 | CRAT 134X55X146 | 134 | 55 | 146 | 83 | 85 | 50 | • | 2 | - | 227,9 | 315 |

The bearings are supplied with 2ZL seals or PP seals, on request

The back-up rolls are grease lubricated according to DIN 51825

Air filling is provided for PDA execution

Dimension H is selected in groups of 0.008 mm

Cw: Dynamic load - Cow: Static load

Technical Characteristics - Back-up rollers with pivot for metal flattening machines

Back-up rollers for metal flattening machines are made in two different executions:

- full complement of cylindrical rollers

- with roller cages in mould steel or bronze.

The full complement execution allows the bearing to reach a high load capacity both dynamic and static.

The wide working surface, along with the rolling system, made of two or more cages, allow the plant to reach very high flattening performance and high speed.

The distance rings, which are obtained entirely on the outer ring and on the pivot, and the circle clearance, which is calculated at the minimum, allow a good support of axial loads.

The execution with roller cages represent the most advanced series of back-up rolls.

This series of back-up rollers is usually manufactured with two lateral thrust bearings in the inner body, either with balls or rollers, which guarantee a very strong support of axial loads.

The distance rings, which are obtained entirely on the outer ring and on the pivot, and the circle clearance, which is calculated at the minimum, allow a good support of axial loads.

The execution with roller cages represent the most advanced series of back-up rolls.

This series of back-up rollers is usually manufactured with two lateral thrust bearings in the inner body, either with balls or rollers, which guarantee a very strong support of axial loads.

Back-up rollers with pivot for metal flattening machines have the following characteristics:

- The outer ring is supplied in UNI 100Cr6/100CrMo7 core hardened steel that can reach hardness 60-2 HRC.

- Once seen the condition of coupling with working cylinders, the degree of hardness can be reduced to 53÷58 on request.

- The profile of the outer ring is usually cambered in order to optimize the distribution of the applied load.

- The pivot is made in two different steel types, according to dimension and shape:

1) core hardened steel UNI 100 Cr6/100 CrMo7;

2) case hardened steel UNI 18 NiCrMo5.

In both cases the degree of hardness is 60-HRC.

- The bearings have a grease lubrication system and are supplied already pre-lubricated. The lubrication system foresees both the entrance and the exit of grease. They can be supplied also in Long-life execution.

- The sealing system is very efficient, it does not allow outer agents (such as, dust, mill scale, humidity) to enter the back-up roll; at the same time, it prevents the leakage of grease.

- Precision class P0; on request the rollers can be manufactured with precision class P5 (DIN 620) and selected in groups.

- On request, they can be manufactured in stainless steel.