Technical Drawing

Exploded View

Home | Products | Track Rollers | Ball joint

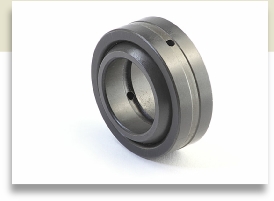

Ball joint

They cannot be disassembled and they have a groove and a hole on both rings to favour the lubrication.

Ball joints with 2RS execution have double lip sliding seals on both sides.

Maintenance-

The outer ring is divided into two parts, which are perpendicular to the axis.

The inner ring is manufactured in UNI 100Cr6/100CrMo7.

Even though the ball joints are maintenance-

C.R. ball joints are provided with groove and holes on both rings, to favour lubrication.

C.R. ball joints have different surface materials and can be divided into two groups:

1 -

2 -

C.R. ball joints have the following technical characteristics:

Steel-

Contact surfaces undergo an additional special treatment, to make them completely resistant to wear.

Technical Characteristics

Ball joints are made of one inner ring with spherical and convex surface, which matches with the concavity of the inner surface of the outer ring.

They are particularly used in case it is necessary to align the shaft to the housing, with low shearing speeds.

Cw : Dynamic load -

D

mm

150

160

180

210

230

260

290

320

340

370

400

430

150

160

180

210

230

260

290

320

340

370

400

430

d

mm

100

110

120

140

160

180

200

220

240

260

280

300

100

110

120

140

160

180

200

220

240

260

280

300

C

mm

55

55

70

70

80

80

100

100

100

110

120

120

67

74

80

95

109

122

134

148

162

175

190

200

B

mm

70

70

85

90

105

105

130

135

140

150

155

165

71

78

85

100

115

128

140

155

170

185

200

212

a

°

7

6

6

7

8

6

7

8

8

7

6

7

2

2

2

2

2

2

2

2

2

2

2

2

b

mm

11,3

11,5

13,5

13,5

13,5

13,5

15,5

15,5

15,5

15,5

15,5

15,5

7,4

7,5

7,5

7,5

7,5

7,5

11,5

13,5

13,5

15,5

15,5

15,5

dk

mm

130

140

160

180

200

225

250

275

300

325

350

375

135

145

160

185

210

240

260

290

310

340

370

110

M

mm

5

5

6

6

6

6

7

7

7

7

7

7

4

4

4

4

4

4

5

6

6

7

7

7

C.R. Rif.

GE 100 FS

GE 110 FS

GE 120 FS

GE 140 FS

GE 160 FS

GE 180 FS

GE 200 FS

GE 220 FS

GE 240 FS

GE 260 FS

GE 280 FS

GE 300 FS

GEP 100 FS

GEP 110 FS

GEP 120 FS

GEP 140 FS

GEP 160 FS

GEP 180 FS

GEP 200 FS

GEP 220 FS

GEP 240 FS

GEP 260 FS

GEP 280 FS

GEP 300 FS

r1 min.

mm

1

1

1

1

1

1,1

1,1

1,1

1,1

1,1

1,1

1,1

1

1

1

1

1

1,1

1,1

1,1

1,1

1,1

1,1

1,1

1

2

r2 min.

mm

1

1

1

1

1

1,1

1,1

1,1

1,1

1,1

1,1

1,1

1

1

1

1

1

1,1

1,1

1,1

1,1

1,1

1,1

1,1

C

kn

610

655

950

1080

1370

1530

2120

2320

2550

3050

3550

3800

600

720

850

1200

1600

2080

2450

3050

3550

4250

5000

5600

Co

kn

3050

3250

4750

5400

6800

7650

10600

11600

12700

15300

18000

19000

900

1080

1270

1800

2400

3100

3650

4550

5400

6400

7500

8300

1. Outer ring

2. Inner ring

3. Outer ring

C.R. s.r.l. -