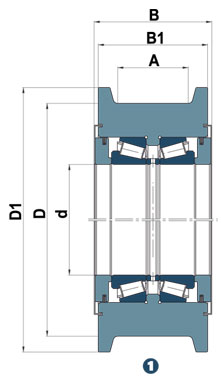

Technical Drawing

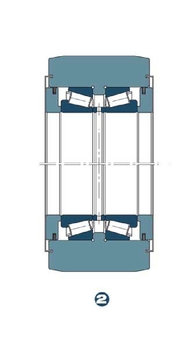

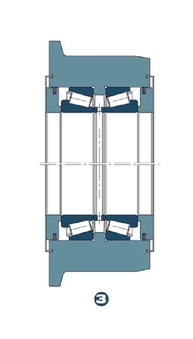

Exploded View

Home | Products | Steel Industry | Tapered rollers for conveyor belts

Tapered rollers for conveyor belts

1) ring with double guide border on the outer surface,

2) ring with outer surface without borders;

3) ring with one guide border on the outer surface.

The rollers have a double protection system, which is made of steel shields and steel elastic layered steel.

Grease lubrication is made through a groove on the inner distance ring.

The execution with tapered rollers is particularly suitable in case of high radial loads and strong axial thrusts, which are due to the shape and the length of the belt.

As the path of transportation is not linear, variations of directions of the applied load should be foreseen.

These tapered roller bearings are fixed in pre-

Tapered rollers for conveyor belts have the following characteristics:

The outer ring is usually supplied in cementation steel UNI 16NiCr4 and reaches hardness

degree of 60-

Technical Characteristics

Series of rollers with different profiles of the outer ring have been developed for various applications in the field of steel industry.

They are mainly used as support bearings in conveyor belts for coils.

C.R. Ref.

900-

900-

900-

900-

900-

900-

C: Dynamic load

Co: Static load

Max speed

RPM min-

2.400

2.100

1.800

1.600

1.300

1.100

D

mm

125

150

165

185

215

255

D1

mm

140

170

190

210

250

290

A

mm

45

55

60

65

75

85

B1

mm

70

80

85

95

105

120

C

KN

98

131

163

219

275

390

Co

KN

177

246

306

426

552

824

d

mm

50

60

70

80

100

120

B

mm

75

85

90

100

115

130

1. Seal sheet

2. Fey seal ring

3. Support thrust ring

4. Tapered roller bearing

5. Distance ring

6. Outer ring

7. Tapered roller bearing

8. Support thrust ring

9. Fey seal ring

10. Seal sheet

C.R. s.r.l. -